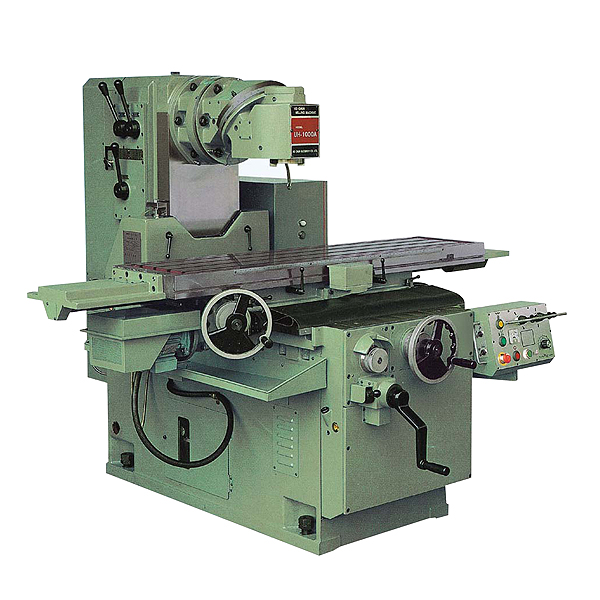

HO CHUN Bed-Type Universal Milling Machine

Last Update

Price:

R.F.Q.

Share Product:

Detail

- The spindle heads, upper and lower part of head can match and revolve in angle so that the machine can mill the working pieces in any direction, vertical, horizontal, tilting, helical, etc.

- Horizontal Position:

The upper and lower head are both fixed at 0° to mill the working piece. When the upper head is fixed at 180° and the lower head is fixed at 0°, it can mill the higher working piece - Vertical Position:

When the upper head is fixed at 0° and the lower head is fixed at 180°, the standing miller can work on the working piece i the way. Besides, beacuse the spindle head can be revolved to any angle, it can do tilting milling and helical milling easily.

- Horizontal Position:

- There is equipment to eliminate backlash on the left-right as well backforth lead screw lever

- The handwheels, handles, etc, which are to be handled, are set at the front of the machine to facilitate operation. A hanging and movable control panel is set to keep the operator safe and to facilitate operation

- Lubricating and Cooling System:

- The speed changing gears and bearings are oil-bathing lubricated

- Automatic lubricating system is to make sure that each sliding face, driving part, and lead screw levers can operate smoothly, to work precisely and to lengthen the working life of the machine

- The coolant pump is set at the right side of the base block; the flow quantity can be adjusted

- The high quality cast iron is used to form the column, the working table, the saddle and the base. The sliding faces are specially ground and treated. The sliding face of the base seat is specially treated with alloy steel. Therefore, the whole machine structure is suitable for heavy milling load and high precision requirement.

- The gears in speed changing box of the column are made of chrome molybdenum alloy steel and are heat treated and ground

- Safety equipments are attached to the automatic back-forth and left-right feed and the elevating feed to make the operation safe

- The horizontal milling arbor accessories can be set, the arbor support and horizontal arm of which are made of high quality strong graphite cast iron so that the arbor can work precisely

- Automatic circulatory accessories can be set. During the operation process, from start to stop, the work piece can be united with left-right feed, back-forth feed, elevating feed, and rapid feed, so that the production can be higher. The damper rigging set can be adjusted.

Standard Accessories

- Coolant Pump

- Tool Box

- Heavy Duty Eye Bolt

- Standard Screw Washer

- L-Shaped Spanner

- Socket Spanner

- Grease Gun

- Shifting Spanner 46mm

- Spindle Drawing Bar

- Adjusting Pin

- Automatic Lubricating system

- Cross Screw Drive (+)

- Cross Screw Drive (-)

- Head Rotary Round Stick

Optional Accessories

- Horizontal arbor accessories

- Milling cutter shank

- Work light

- Universal dividing head

- Rotary vise 150mm

- Milling cutter 6', 8', 10'

- Helical milling accessories

- Magnetic chuck

- Digital readout with linear scales for X, Y, Z axis

- Ball screws for X, Y, Z axis

- Electric auto spindle brake system

- Hydraulic tool clamping system

Specification

| Keyword | |

| Brand | |

| Origin | SG |

Catalogue Download